Technologies

at Scale

Our fast-upcoming greenfield facility in Jagiroad, Assam, is slated to begin operations in 2025. Our investment of over $3 billion will attract a global ecosystem to India, enhancing supply chain resilience.

Our portfolio of traditional and advanced packaging technologies, delivered at scale, provides competitive advantages to our global customer base.

Our Locations

First Commercial Facility, Vemgal, Karnataka

- State-of-the-art facilities

- World class equipment

- ISO 9001 certified

- Operational since Dec 2023

First Commercial Facility, Vemgal, Karnataka

HVM Greenfield Facility, Jagiroad, Assam

HVM Greenfield Facility, Jagiroad, Assam

- USD 3Bn+ investment

- 600-acre campus near Guwahati

- 100% renewable energy

- Ready for high volume manufacturing by mid 2025

1000+

years of combined expertise

600-acre

Large campus

$3+ Bn

investment

15+ Bn

chips per year capacity

Join Us

AI-enabled

factories

3

packaging technology & expanding

100% renewable power from day 1

2 Mn ft 2

operational area, 50% cleanroom space

Our Capability

Our proven expertise enables us to address the evolving needs of the semiconductor market, providing a complete range of solutions from packaging to testing and failure analysis.

- Package Design

- Wafer/Die Preparation

- Interconnection

- Finishing

- Testing

- Failure Analysis & Reliability

Package Design

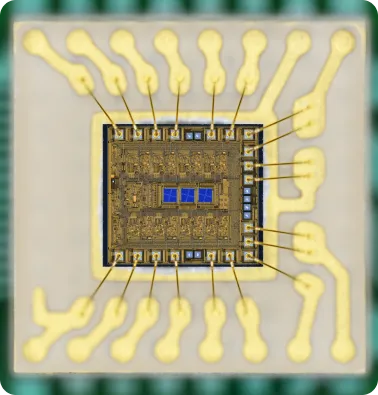

IC Package Design is a vital step in semiconductor manufacturing that determines how an integrated circuit (IC) is interconnected, encapsulated, and integrated with external systems. The design ensures the IC functions optimally by addressing key factors such as electrical performance, thermal management, mechanical protection, and long-term reliability.

Wafer/Die Preparation

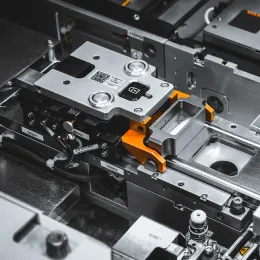

Wafer/Die Preparation transforms a silicon wafer embedded with integrated circuits (ICs) into separate functional chips. This process includes essential steps like thinning the wafer, singulating the wafer into individual dies, and pick-and-place.

Interconnection

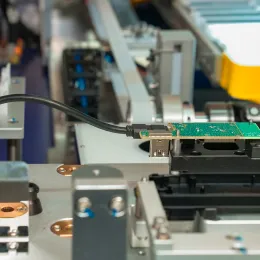

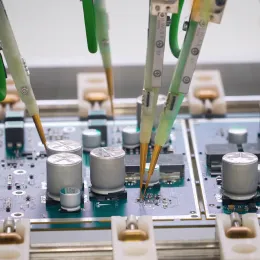

Interconnection in IC packaging establishes electrical connections between the IC die and external systems, impacting performance, signal integrity, reliability, and functionality. The choice of technique-such as wire bonding, flip-chip, or TSVs depends on the IC's performance needs, package type, space and cost constraints.

Finishing

Finishing involves molding or encapsulating the die for protection, followed by deflashing, which meticulously removes any surplus molding compound. Then, laser marking provides permanent identification and traceability. Finally, singulation separates individual units from the lead frame or substrate, preparing the IC for final testing and shipment.

Testing

Testing in IC Packaging is an essential step that ensures the integrated circuit (IC) functions as intended, remains reliable over its lifespan, and meets all required performance specifications after packaging. This phase is essential for verifying the IC's functionality, durability, and quality before it is integrated into final products, ensuring that it meets the standards for real-world application.

Failure Analysis & Reliability

Failure Analysis is a systematic approach used to investigate and identify the root causes of IC failures, focusing on packaging and interconnect issues. It helps improve designs and prevent future failures and reliability evaluates how ICs perform under operational stresses like thermal cycles, mechanical shocks, vibrations, and humidity. This testing ensures the IC will maintain performance and durability in real-world conditions.

Market Segments

We are focusing on a diverse array of market segments with our packaging technologies.

Artificial Intelligence

Mobile

Storage

Internet of Things

Automotive

Radio Frequency

Certifications

Certification Roadmap

Partnerships

We have tied up with premier institutes for further innovations and technical collaborations.

Indian Institute of Management, Mumbai

Executive MBA in Manufacturing Management

Sastra University

MTech. in VLSI